Rutgers' Drone Team

RUAuto

See you at

SUAS 2025 🎉

RUAuto is competing in the Student Unmanned Aerial System (SUAS) competition!

SUAS is an annual competition where schools from across the world (including Cornell, UPenn, UT-Austin, etc) fly their custom-built vehicles.

We strive to grow and improve every year!

What is SUAS?

For the SUAS competition teams are tasked with building an autonomous vehicle from scratch. That's right, it needs to be able to fly and complete tasks all on its own 😎. This includes taking off and landing, waypoint navigation, object detection and classification, and payload delivery.

Rutgers has a pretty good record at SUAS, and we're constantly learning and improving as we grow!

We just love aviation ✈️

We’ve built all kinds of drones, like quadcopters, hexacopters, and even many FPV drones 🤩!

The only thing that stays the same is our team’s work ethic and relentless passion for designing high-quality hardware and software.

At SUAS 2025, we’re flying our beloved quadcopter! She’s fast, nimble, and ready to win 🥇 (or at least do her best)!

Meet our core team

Everett Murray

Team Captain

Rishabh Narayanan

Autopilot Lead

Hena Patel

Hardware Lead

Nolan Carr

Airdrop Lead

Alejandro Pinto

Imaging Lead

Drone Design

Hardware

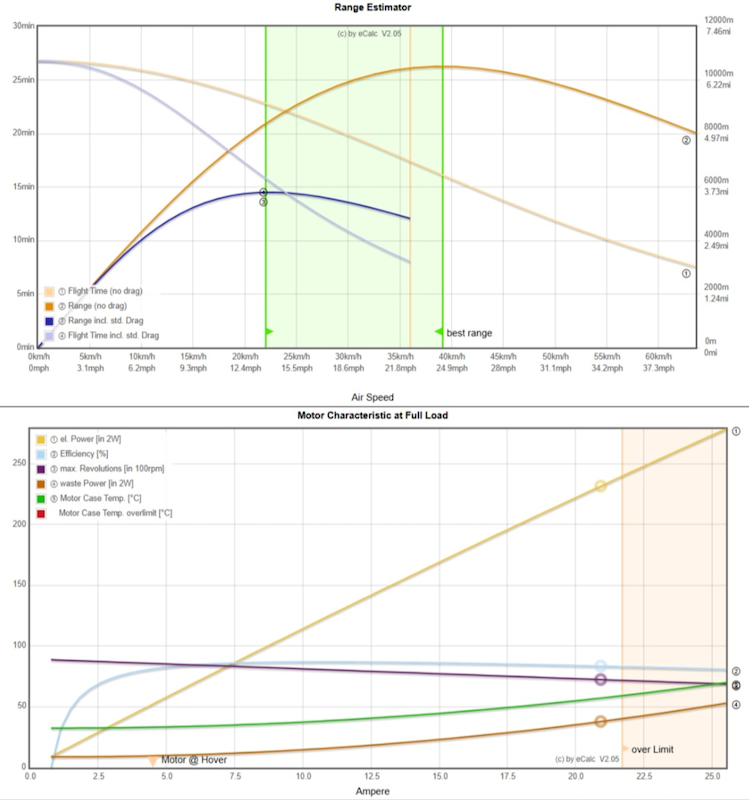

eCalc Optimization

eCalc is a powerful industry-standard tool to calculate various metrics about custom vehicles. We use eCalc to measure and optimize battery weight, battery power, propeller diameter, propeller pitch, motor KV, ESCs, etc.

With eCalc, we first fine-tune our drone’s parameters to ensure maximal performance. Then we move on the designing and building.

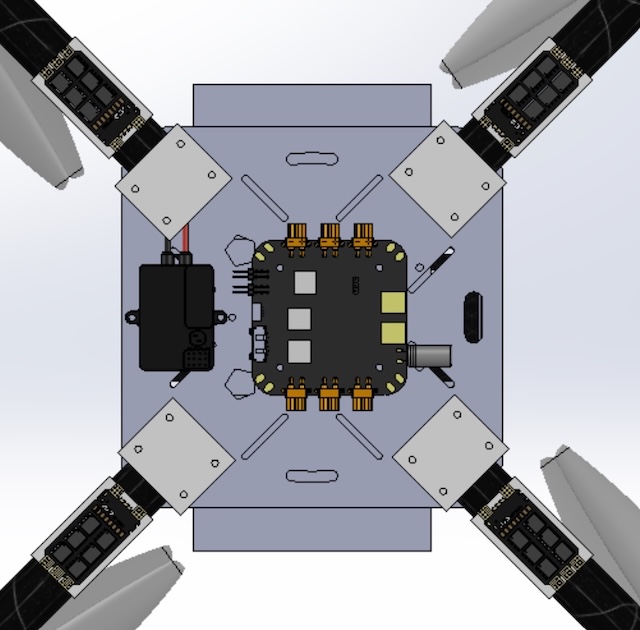

3D Modeling

Once our optimal drone has been configured using eCalc, we then move on to designing the frame in 3D CAD software.

We use SolidWorks to precisely measure and machine drone parts, include motor plates, mounting brackets, and component housing. Here's one of the models we built for the central plate.

Quadcopter

One of our most pivotal decisions was to build a quadcopter for this year’s competition. Our team considered various other form factors, like a hexacopter and a coaxial quadcopter.

However, we settled on the quadcopter because we calculated that a lightweight, fast drone would be able to complete the multi-lap course more efficiently.

Airdrop

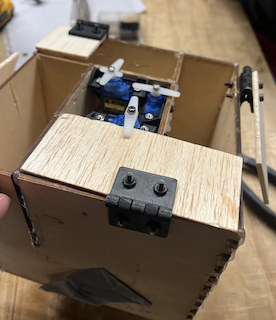

Iterative Designing

Just like hardware, our airdrop team begins first and foremost with designing our payloads in popular 3D software, like SolidWorks.

We’ve gone through many iterations to optimize the payload housing, and decided with a ring like structure. This ensures even weight distribution while allowing a centralized area for routing servos and cables.

Safe Delivery

To safely drop each payload, we considered various different options, namely winches and parachutes. Although winches offer more precision, they require the drone to be hovering in place for longer.

To optimize on speed, we elected for parachutes to ensure our drone could accurately deliver a package and immediately move on to the next task.

Imaging

Computer Vision

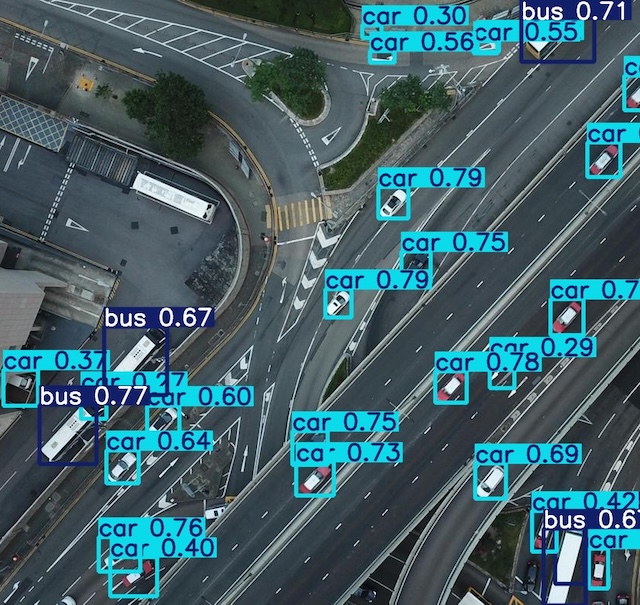

We aggregate numerous high-quality datasets, including COCO and VisDrone to train our machine learning models.

Once data is collected, we train and validate a YOLO model to identify and classify points. “You Only Look Once (YOLO)” models were intentionally selected to combine object detection and classification for faster data recognition.

Map Stitching

Just like Google Earth, one of our tasks this year is to stitch many images to form a single high-quality map. Image stitching involves identifying shared features among images to merge them.

Our team integrates GPS data with image data to ensure our stitching algorithm is high-quality. We use OpenCV and image processing to ensure a more consistent image quality.

Autopilot

Ground Control Station

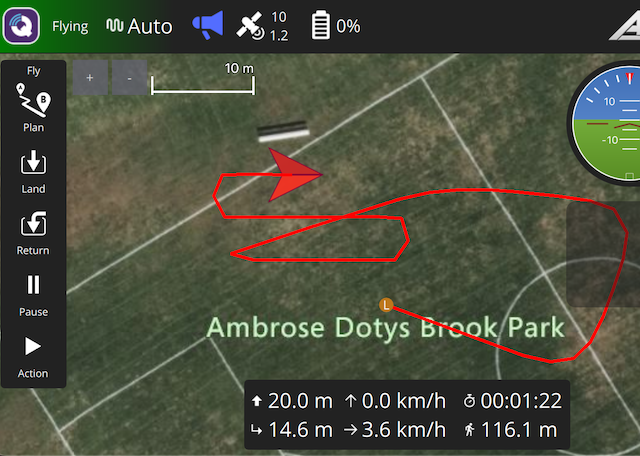

For monitoring our drone as it flies, we use the popular open source software QGroundControl.

With QGroundControl, we can plan missions, navigate waypoints, perform safety checks, and calibrate our drone for optimal performance.

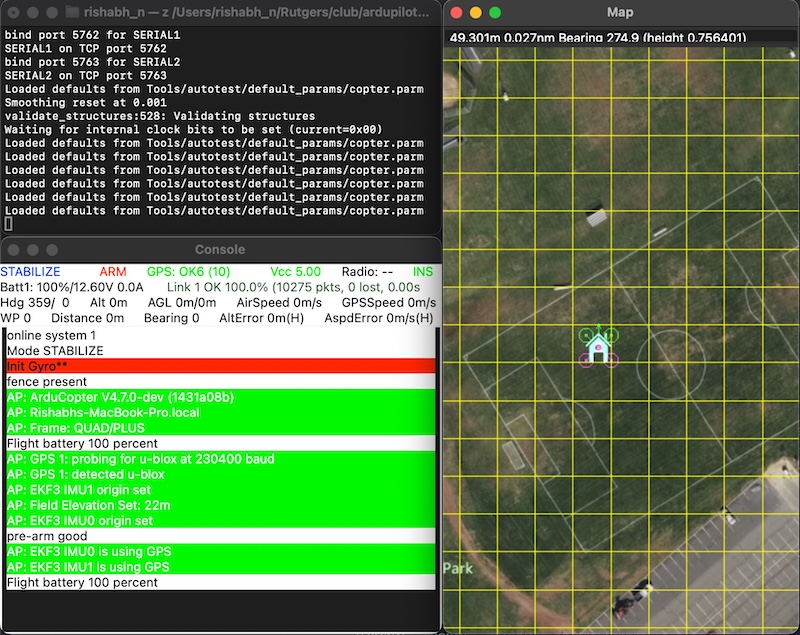

Software Simulation

It’s unsafe and expensive to test new code on our physical drone, so we use ArduPilot’s SITL (software in the loop) to simulate a safer environment.

Basically, we simulate the flight controller (Pixhawk) and environment to trick our code into believing it’s running on the real thing!

MAVLink Protocol

Instead of sending data back to the ground for processing, our code runs directly on the drone. We use python and the pymavlink library to command our drone from this onboard computer.

We intentionally designed our system this way to minimize latency and to ensure our drone can fly even under a shaky connection with the ground.

Monthly Blog

Apr 2025

April marked the culmination of the development process, with a strong emphasis on comprehensive system integration and rigorous flight testing of the fully assembled drone under realistic operational conditions mimicking the competition environment. Meticulous evaluation and optimization of key performance metrics were conducted, including detailed analysis of flight stability (assessing attitude control and vibration levels), navigation accuracy (evaluating GPS precision and waypoint tracking), object detection rates and accuracy (quantifying the model's ability to correctly identify target objects with minimal false positives), payload delivery precision and reliability (measuring the accuracy and consistency of payload releases at designated locations), and overall flight endurance (monitoring battery consumption and achievable flight time). The team systematically addressed any remaining integration challenges through meticulous debugging of hardware and software interfaces, fine-tuning control parameters within the flight controller software (e.g., PID gains, navigation parameters), and making final mechanical adjustments to ensure smooth and reliable operation of all subsystems. Extensive testing protocols were implemented to verify the robustness and reliability of the entire drone system, including simulated mission runs, stress tests of individual components and the integrated platform, and thorough pre-flight checklists. The data gathered from these intensive flight tests directly informed final optimization efforts, leading to adjustments in flight control parameters, object detection model thresholds, image processing pipelines, and payload release timing to maximize overall performance and ensure mission success during the competition.

We're grateful for

Our Sponsors ♥︎

98 Brett Road, Piscataway, NJ 08854

rutgersaiaa@gmail.com